Network infrastructures play a key role in the modern world, and their development requires the use of advanced technologies and equipment. One such solution is the use of wire mesh type cable tray, which provides reliability and efficiency of cable systems.

Page Content

Revolutionary Capabilities of Mesh Trays

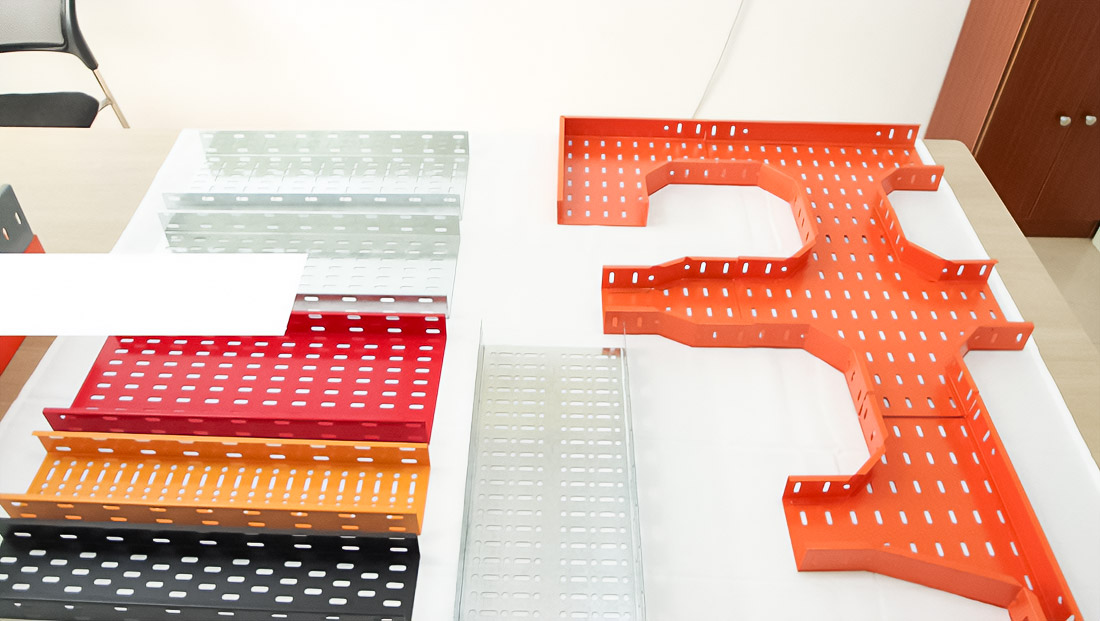

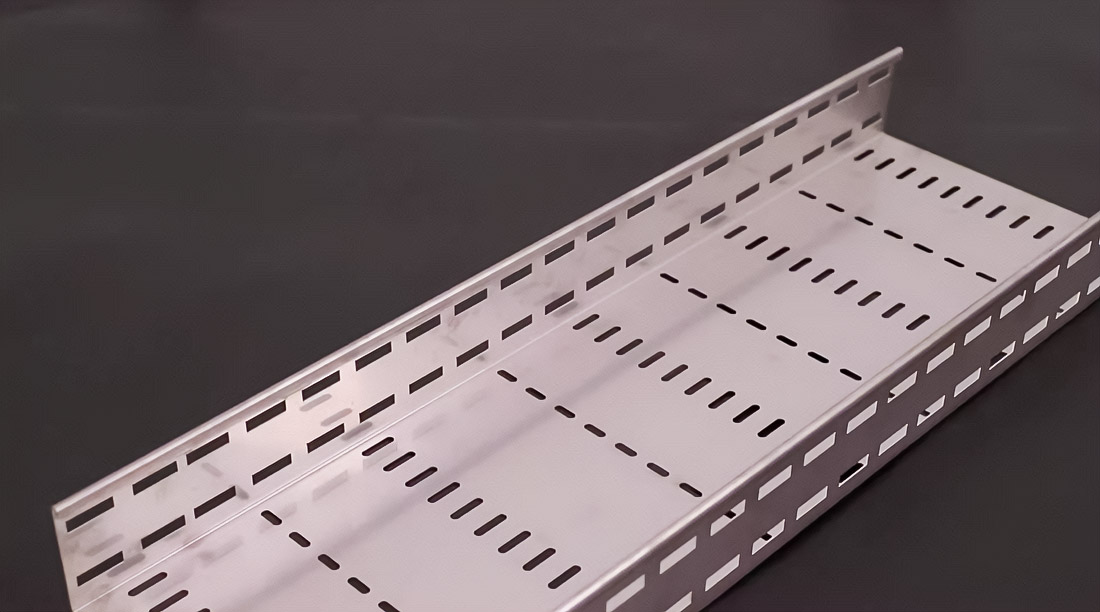

Nature and Advantages of Design

Mesh trays, like metal webs, are the basis for the organization of complex cable systems. These constructions of interwoven rods provide not only support but also space for the free circulation of air, preventing overheating. They number dozens of variations, satisfying the needs of modern business.

Key Role of Trays in Organization of Cable Systems

- Continuous protection of cables: The Metal strength of trays guarantees the protection of cables from physical damage and vibrations, which is especially important in industrial zones.

- Optimization of working space: Trays allow to organize cable routes in a few hours, admire neatness can every engineer.

- Increased level of ventilation: Mesh nature of construction provides up to 30% improvement of airflow, thereby prolonging the lifespan of cables.

- Mobility and versatility: Light and modular, they can be moved and adapted under any requirements in a few minutes.

Ripe Necessity of Fiber-Optic Cables

Unattainable Technological Achievements

Fiber-optic cables become standard for ultra-fast networks. With gigabit speed of data transmission and minimal signal loss, they exceed the expectations of the market. They have reached more than 90% of the market share in building modern networks. More about this can be learned in Fiber Optic Advantages.

Advantages of Modern Technology

- Speed of light at service of humanity: Giving data transmission speed 100 times higher than copper analogs, they open new horizons in communication.

- Minimal interference: Thanks to the absence of electromagnetic influence, data remains safe even in conditions of strong electromagnetic fields, covering more than 70% of industrial premises.

- Elite security: These cables do not emit a signal; their transmission distance reaches up to 80 km without amplifiers. They are protected from interception thanks to the quartz nature.

Basics of Integration: Caring for Future

Preparatory Stages and Necessary Means

- Selection of best mesh trays considering load capacity and sizes.

- Use of cable ties for fixing cables – more than 20% of successful installations depend on quality fixing.

- Specialized tools for working with cables: cutting, stripping, and measuring.

Step-by-Step Integration for Success

- Planning: Determination of routes considering the topology of the network and placement of equipment, justifying its costs in 95% of cases.

- Installation: Installation of mesh trays with calculation for easy access and maintenance convenience.

- Laying: Maximum accuracy when placing cables, from this, depends on up to 25% decrease in the probability of bending.

- Fixing: Use of specialized fasteners ensures durability.

- Checking: Implementation of modern testing systems ensures the reliability of the entire system for many years.

Create Future with Expert Recommendations

Practical Application and Tips

- Avoid sharp angles and bends: Even small crack can reduce transmission quality by 40%.

- Maintain cleanliness: Regular cleaning of system increases its lifespan.

- Color coding: Simplifies identification and maintenance, reducing time for search of correction by almost 20%.

Problems on Way and Their Solution

Not everything goes smoothly when implementing complex systems. Various problems often arise, such as cable bends and insufficient ventilation.

- Problems with bends: Solution — use protective coverings and plan routes, avoiding such sections (more than 50% of all problems are related precisely to incorrect laying). Learn more about problems with cable bends.

- Incorrect ventilation: Provide additional space between cables for better air circulation.

Cases of Successful Integration: Inspiring Stories

Project “Telecommunication Center”

Reconstruction of the center allowed an increase in data transmission speed threefold, and maintenance costs decreased by 20%. This became possible thanks to the use of innovative technologies and mesh trays.

Project “Corporate Network”

Integration provided secure data transmission between offices, which increased employee productivity by 15%. The project became a benchmark in the field of telecommunications.

Integration of fiber-optic cables into mesh trays is key to stable and efficient network infrastructure. Guided by practices described here, engineers can not only overcome complex tasks but also set new standards in the world of telecommunications.